In the realm of construction, two materials stand out as cornerstones of modern infrastructure: steel and concrete. These materials have played pivotal roles in shaping the skylines of cities, constructing bridges that span great distances, and erecting buildings that withstand the test of time.

While both are essential, each possesses distinct characteristics that make them suitable for different applications.

In this comprehensive exploration, we delve into the fundamental differences between steel and concrete, their unique properties, advantages, limitations, and their significance in contemporary construction practices.

- Origins and Composition:

- Steel: Steel is an alloy primarily composed of iron and carbon, with trace amounts of other elements such as manganese, silicon, and phosphorus. The addition of carbon imbues steel with strength and durability, making it an ideal material for structural applications.

- Concrete: Concrete, on the other hand, is a composite material comprised of cement, aggregates (such as sand and gravel), and water. Cement acts as a binding agent, binding the aggregates together to form a solid mass. Concrete’s versatility stems from its ability to be molded into various shapes and sizes, offering flexibility in construction projects.

- Structural Properties:

- Steel: Steel exhibits exceptional strength-to-weight ratio, allowing for the construction of towering skyscrapers and long-span bridges with relatively lighter structural elements. Its ductility enables it to withstand dynamic loads and seismic forces, making it suitable for high-rise buildings and earthquake-prone regions.

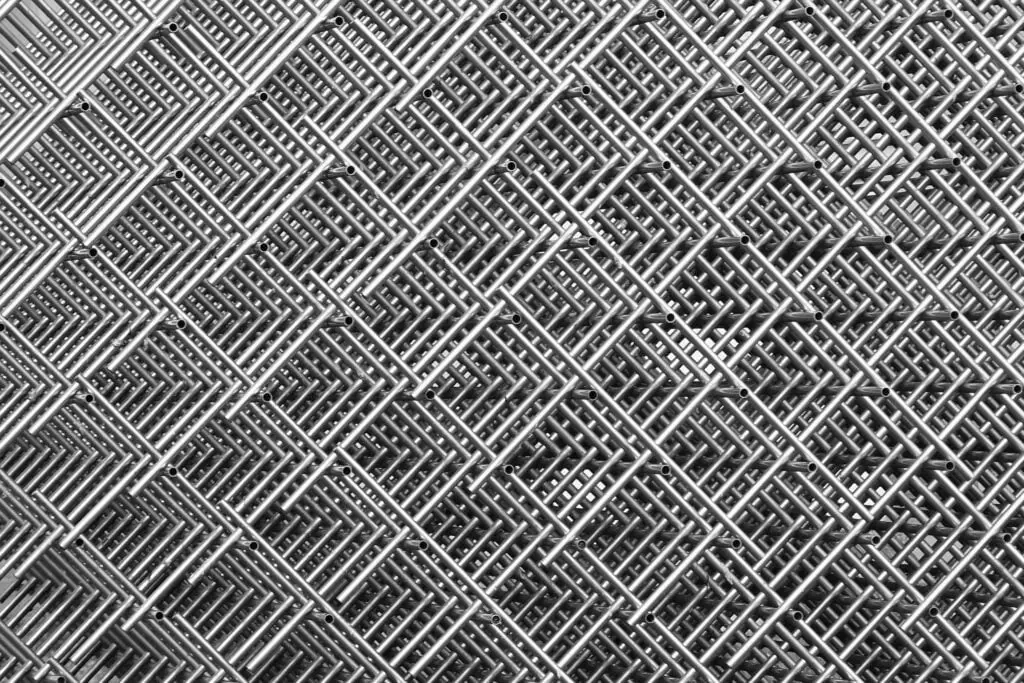

- Concrete: Concrete is renowned for its compressive strength, making it ideal for supporting heavy loads and resisting compression. While not as strong in tension as steel, concrete structures compensate by incorporating reinforcement bars (rebar) to enhance tensile strength, creating durable and resilient structures.

- Construction Process:

- Steel: The fabrication and erection of steel structures involve precision engineering and meticulous planning. Steel components are fabricated off-site, allowing for efficient assembly on-site, reducing construction time and labor costs. The versatility of steel permits rapid construction, making it advantageous for projects with tight schedules.

- Concrete: Concrete construction typically involves casting the material on-site into formwork, allowing for customization and adaptation to specific project requirements. The curing process is critical, as it determines the strength and durability of the concrete structure. While concrete construction may take longer compared to steel, it offers versatility in design and adaptability to various architectural styles.

- Environmental Impact:

- Steel: The production of steel involves significant energy consumption and carbon emissions, primarily attributed to the extraction of raw materials and the smelting process. However, steel is highly recyclable, with recycled steel retaining its properties and reducing the demand for virgin materials, thus mitigating its environmental footprint.

- Concrete: Cement production, a key component of concrete, is energy-intensive and contributes to greenhouse gas emissions, particularly carbon dioxide (CO2). Additionally, the extraction of aggregates can lead to habitat destruction and environmental degradation. Efforts to reduce the carbon footprint of concrete include the use of alternative cementitious materials and sustainable aggregate sources.

- Maintenance and Durability:

- Steel: Steel structures require regular maintenance to prevent corrosion and ensure structural integrity. Protective coatings, such as paint or galvanization, are applied to steel surfaces to mitigate corrosion and extend the lifespan of the structure. Proper maintenance practices are essential to prolong the durability of steel infrastructure.

- Concrete: Concrete structures are renowned for their durability and resistance to weathering, requiring minimal maintenance over their lifespan. However, factors such as exposure to harsh environments, chemical corrosion, and seismic activity can degrade concrete over time. Adequate design measures and preventive maintenance help enhance the longevity of concrete structures.

- Cost Considerations:

- Steel: While the initial cost of steel may be higher compared to concrete, the efficiency of steel construction often translates to cost savings in labor, construction time, and project management. The versatility of steel enables rapid construction, reducing overall project costs and delivering value for investors.

- Concrete: Concrete construction offers competitive pricing, particularly for projects that prioritize long-term durability and minimal maintenance. The availability of locally sourced materials and standardized construction techniques contribute to cost efficiency in concrete projects. Additionally, the versatility of concrete allows for creative design solutions within budget constraints.

Conclusion:

In conclusion, steel and concrete represent indispensable building materials in the realm of construction, each offering unique properties and advantages. While steel excels in its strength, flexibility, and rapid construction capabilities, concrete boasts durability, versatility, and competitive pricing.

Understanding the fundamental differences between steel and concrete enables engineers, architects, and construction professionals to make informed decisions in selecting the most suitable material for their projects.

Ultimately, the synergy between steel and concrete continues to shape the urban landscape, driving innovation and sustainable development in the construction industry.

To see other material construction, please see here.

To know other construction guides, tips, and methodology for beginners, veterans, and contractors, please see here.