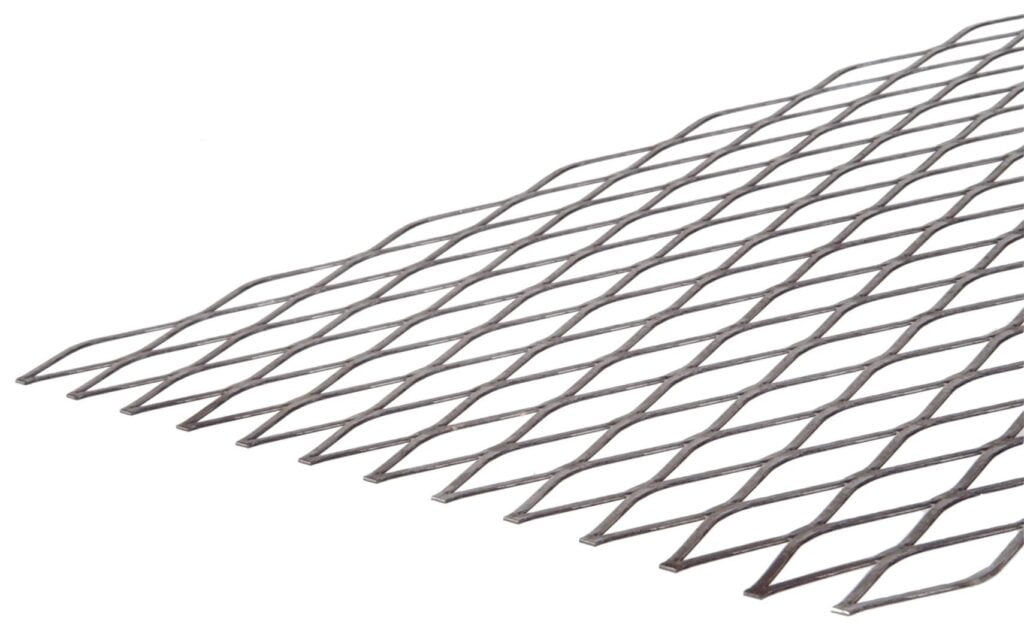

What are the Guaranteed Material Types of Expanded Metal?

Expanded metal also has the advantage of never being totally sliced and reconnected, preserving the strength of the material.

What are the Guaranteed Material Types of Expanded Metal? Read More »