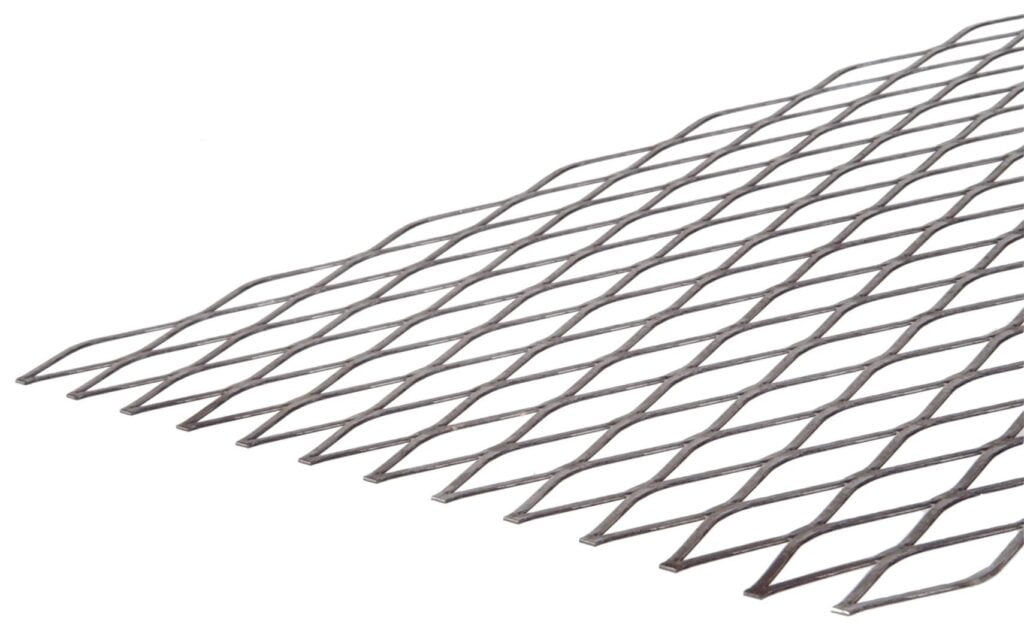

What are the Guaranteed Material Types of Expanded Metal?

Because the material is flattened and stays in one piece, expanded metal is stronger than an equivalent weight of wire mesh, such as chicken wire. Expanded metal also has the advantage of never being totally sliced and reconnected, preserving the strength of the material.

Diamonds are the most preferred shape because of how efficiently it absorbs energy and resists mechanical deformation after installation. Other often used shapes include squares, circles, and diamonds. The forms’ dimensions and angles should also be taken into account because they have an impact on how well the metal absorbs energy and how the energy is distributed throughout the expanded metal.

The two acute and two obtuse angles are two of the four angles that must be taken into consideration for the diamond shape. The strength of the shape will decrease as the angles increase since there will be more internal space. However, if the angles are too narrow, the structure loses strength because the shapes are too close together and cannot support themselves.

A key factor is the angle at which the forms are set out. If the angle is 0, the shape’s ends point to the beginning and end of the diamond sheet, creating straight lines there. When it comes to flattening the sheet on its side, this choice offers the strongest compression. Because the sheet will compress and disperse the pressure across it, it can withstand much greater pressure than a solid piece of metal. The remaining four often employed angles are 60o, 90o, 90o plus 60o, and 60o plus 90o. The diamond diagonal is located at the beginning and end of the sheet at a 60° angle.

The 60o and 90o angles are combined in the 90o plus 60o and 60o plus 90o angles, respectively; the order of the angles corresponds to the order in which they are named. The expanded metal can be produced and delivered as conventional mesh or it can be flattened by adding more leveling charges to create a smooth surface that enables the use of mesh in more applications, such as prison protection to prevent injured hands from touching the mesh.

Technically, expansion is possible with any malleable metals. Many of these, meanwhile, cannot be successfully developed on an industrial scale. These materials are covered in some detail below.

Copper Expanded Metal

If just structural considerations are made, copper is not typically the primary material of choice. In addition, copper is somewhat more expensive, particularly when rated per unit volume. The volume parameter is particularly significant since it affects the final dimensions of the expanded metal sheet. The high specific weight of copper is a drawback where weight is an issue, like in rigging.

When there are substantial worries about more than just the structure, copper is used. Such comprise:

Corrosion resistance is crucial when the expanded metal sheet is exposed to moisture or other corrosive environments as part of its intended application.

Electrical conductivity: Compared to the majority of industrially available metals, copper is a better electrical conductor.

Appearance – Copper might be a nice option when the mesh is meant to be attractive.

Copper is more easily sliced and stretched into more complicated shapes due to its malleability.

Expanded Aluminum

Aluminum offers a wide range of structural applications. It is reasonably lightweight and robust. Additionally, it is a good conductor—good enough to serve as the primary component of overhead power cables.

Due to its malleability, aluminum is more easily worked than steel (when cold). Additionally, it resists rusting. It is a suitable choice for high temperature applications due to its high melting point and good thermal reflectivity.

Expanded Steel

Expanded metal is widely used to create fences, walkways, and grates because it is far more sturdy and long-lasting than wire mesh, which is lighter and less expensive[dubious – discuss]. The material has numerous tiny gaps that permit light, water, and air to pass through while yet acting as a mechanical barrier to bigger items. Expanded metal has another benefit over plain sheet metal in that its exposed edges offer additional traction. As a result, it is frequently used in drainage covers and catwalks.

The most popular structural metal is steel. For as long as it is not rusted, it has the highest strength of all the metals featured in this compilation. Steel comes in a variety of forms.

- Expanded Mild Steel

- Grating Metal Sheet

- Stainless Steel Expanded Metal

To know more about How to Apply Building Permit in the Philippines

To know other construction guides, tips, and methodology for beginners, veterans, and contractors, please see here.

To know the flood prone areas in the Philippines, Top 10 Flood-Prone Areas to Live in the Philippines.

To know more about Concrete Hollow Blocks, Simple Reasons Why Hollow Blocks are Highly Used in the Philippines

To know more about Surface Materials, What is the Best Surface Material: Laminate Vs. Veneer Vs. Solid Wood

To know more about House Construction, How to Build a House Cheaply: 7 Simple Ways to Save on Home Construction