What is Tubular Steel?

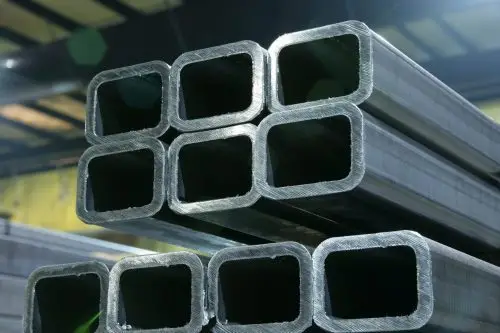

Steel that has been formed into a cylinder or a long, thin rectangle is known as Tubular Steel.

This group includes hollow sections, steel pipes, and tubes since they are all formed like tubes and have a hollow center.

Tubular Steel tubes are a form of metal profile having a hollow tube cross-section. They are also known as hollow structural sections (HSS). It is robust, tough, and long-lasting.

Is it possible to weld it?

Due to its adaptability, tubular steel tubes can be used in a wide range of industries. Millions of tons of steel tubes are produced annually.

Steel tube is an adaptable material that comes in round, square, and rectangular forms.

It is often constructed of several alloys, such as aluminum and titanium, which offer its strength and other significant features.

How Steel is made?

The type of tube determines the process used to make tubular steel. Similar to pipe, a tube can be seamless, formed from a single block of steel, or it can be constructed by welding two parts together to form a whole.

Should the tube consist of two parts, they are welded together after being cast independently. A single block of steel is heated and driven through a number of dies during the extrusion process, which produces the desired tubed shape with the central well, if the tube is seamless.

How strong is Tubular?

Heat exchangers, stairwell handrails, truck and trailer building—among many other applications—benefit greatly from the strength, durability, and affordability of tubular steel tube.

Steel tubing solutions for specific purposes are available, along with a variety of typical diameters and profiles, from numerous steel hardware stores in the Philippines.

This steel tube has been heated to extremely high temperatures and passed through a series of rollers to make it easier to work with. Hot rolling relieves internal tensions.

Although this kind of tube is utilized in the building industry, precision applications are not a good fit for it.

Is Steel Tube Durable?

The short answer is that it is quite robust.

The basic qualities of tubular steel have not changed much throughout time, despite technological advancements in welding, cutting, and bending techniques.

It is a multipurpose, lightweight, and long-lasting material with many potential uses.

Main Uses and Application of Tubular Steel

Scaffolding is the most prevalent application of tubular steel in the construction industry.

But because of its extreme endurance, it’s also utilized in the building of long-lasting constructions like railings and bridges.

Long-distance transportation of gas and water as well as the movement of gas and oil from gas wells to processing facilities or refineries are two more uses and applications for tubular steel.

Because the hollow parts of tubular steel are strong, lightweight, and heat resistant, the aircraft sector also uses it.

In addition, tubular steel finds use in tool bodies, machine frames, and engine components, among other applications in equipment.

Additionally, it is widely used in the automotive industry to make roll bars, exhaust systems, and suspension parts.

Structural Advantages of Tubular Steel

Steel has significant structural benefits due to its great tensile strength and the inherent strength of tubular steel.

It is resistant to extremes in temperature, pressure, and weather, including wind and water.

Tubular steel is widely utilized in the oil and gas industries due to its various structural advantages. It can safely transport chemicals and volatile liquids over long distances and is not prone to breaking or splitting.

What is the Standard Size of Tubular Steel Tube?

There are various sizes of tubular steel or steel tube in the Philippines.

But the most commonly available in commercial hardware are 2″ x 2″ x 2 mm, 4″ x 4″ x 4 mm, 25 mm x 25 mm x 1.0 mm and 50 mm x 50 mm x 1.0 mm.

The table below shows the latest retail April 2024 prices of Tubular Steel in Philippines Peso price per pieces including size, standard length and dimensions.

Price and Standard Size of Tubular Steel or Steel Tube per pc In the Philippines

| DESCRIPTION | LENGTH | SIZE / DIMENSION | UNIT | PRICE |

| Tubular Steel Tube | 6.0 m | 20 mm x 20 mm x 1.0 mm | PCS | 410.00 |

| Tubular Steel Tube | 6.0 m | 25 mm x 25 mm x 1.0 mm | PCS | 555.00 |

| Tubular Steel Tube | 6.0 m | 32 mm x 32 mm x 1.0 mm | PCS | 745.00 |

| Tubular Steel Tube | 6.0 m | 50 mm x 25 mm x 1.0 mm | PCS | 720.00 |

| Tubular Steel Tube | 6.0 m | 25 mm x 25 mm x 1.2 mm | PCS | 760.00 |

| Tubular Steel Tube | 6.0 m | 32 mm x 32 mm x 1.2 mm | PCS | 404.00 |

| Tubular Steel Tube | 6.0 m | 50 mm x 25 mm x 1.2 mm | PCS | 595.00 |

| Tubular Steel Tube | 6.0 m | 50 mm x 50 mm x 1.2 mm | PCS | 890.00 |

| Tubular Steel Tube | 6.0 m | 75 mm x 50 mm x 1.2 mm | PCS | 990.00 |

| Tubular Steel Tube | 6.0 m | 100 mm x 50 mm x 1.2 mm | PCS | 1050.00 |

| Tubular Steel Tube | 6.0 m | 150 mm x 50 mm x 1.2 mm | PCS | 1755.00 |

| Tubular Steel Tube | 6.0 m | 25 mm x 25mm x 1.5 mm | PCS | 822.00 |

| Tubular Steel Tube | 6.0 m | 32 mm x 32 mm x 1.5 mm | PCS | 1300.00 |

| Tubular Steel Tube | 6.0 m | 50 mm x 25 mm x 1.5 mm | PCS | 1144.00 |

| Tubular Steel Tube | 6.0 m | 75 mm x 50 mm x 1.5 mm | PCS | 1250.00 |

| Tubular Steel Tube | 6.0 m | 100 mm x 50 mm x 1.5 mm | PCS | 1350.00 |

| Tubular Steel Tube | 6.0 m | 150 mm x 50 mm x 1.5 mm | PCS | 2100.00 |

| Tubular Steel Tube | 6.0 m | 2″ x 2″ x 2 mm | PCS | 3750.00 |

| Tubular Steel Tube | 6.0 m | 4″ x 4″ x 4 mm | PCS | 2150.00 |

| Tubular Steel Tube | 6.0 m | 2″ x 6″ x 2 mm | PCS | 3550.00 |

| Tubular Steel Tube | 6.0 m | 3″ x 1″ x 2 mm | PCS | 2050.00 |

UPDATED: Construction Material Prices for Tubular Steel in the Philippines (April 2024)

UPDATED: All Construction Prices are based on retail prices around hardware in Metro Manila

To see other material construction, please see here.

To know other construction guides, tips, and methodology for beginners, veterans, and contractors, please see here.