Cable Tray Guaranteed Best Construction Material Philippines’ Prices

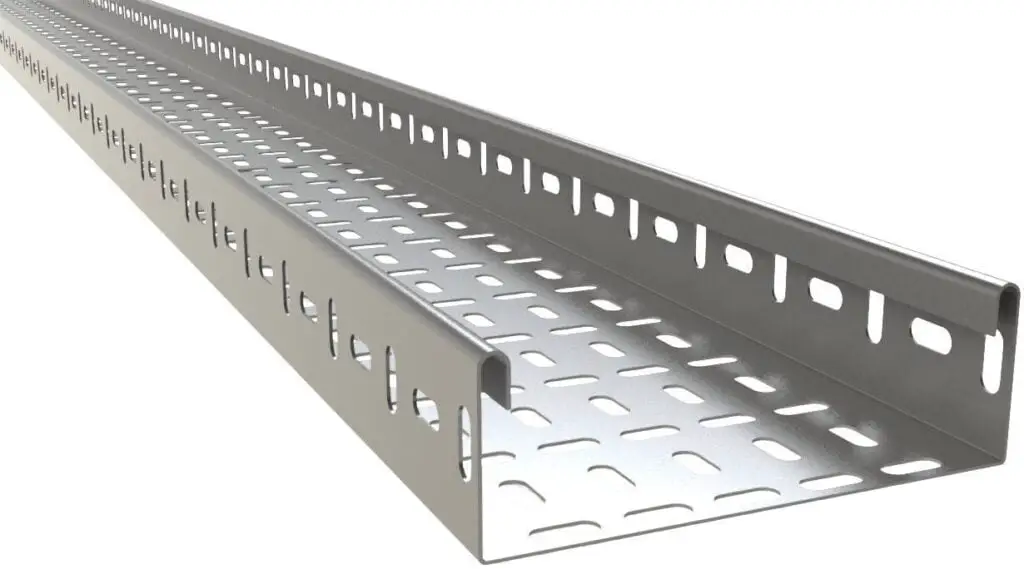

Electrical cables, raceways, and insulated conductors used for electric power distribution, control, signal instrumentation, and communication are mechanically supported by cable trays, which offer a rigid structural framework.

Aluminum, stainless steel, and galvanized steel are the materials used to make metal cable trays.

Glass-fiber reinforced plastic is used to make non-metallic cable trays.

Specific types include:

- Metal channel-type

- Single Metal rail

- Nonmetallic and metallic ladder-type

- Metal and nonmetallic trough-type

- Wire mesh and Metal basket

- Other cable tray systems

The most amount of air can freely travel through the cables in a ladder cable tray without covers.

This enables the cable’s conductors to effectively disperse the heat they produce.

Under these circumstances, a correctly built cable tray wiring system’s conductor insulation won’t heat up over its maximum operating temperature.

The cables won’t deteriorate too soon from high operating temperatures.

When the locations of the cables in horizontal cable tray runs must be maintained or in non-horizontal cable tray runs, the rungs of the ladder cable trays serve as ideal anchors for tying down the cables.

For setups using single conductor cable, this feature is essential.

If the single conductor cables are not firmly secured to the cable tray, the magnetic forces generated by the fault current will pull them free during fault conditions (short circuit).

Ladder cable trays allow cables to enter or depart at either their top or bottom.

The conduit to cable tray clamps can be installed upright or upside-down to terminate conduits on the top or bottom of the cable tray side rail, depending on where the cables enter or depart the conduit.

Ladder cable trays prevent moisture from building up.

Installation of small diameter cables, such as control instrumentation, signal, etc., may be facilitated by hand access through the cable tray bottom if working space is a concern.

The ladder cable tray’s most typical rung spacing is 9 inches.

All sizes of cables can be supported by this gap. Since the support distance prevents any discernible sagging of the small cables between rungs, this spacing is ideal for the small diameter Type PLTC and TC cables.

Although the 12 or 18 inch rung spacing provide appropriate cable support, some installers may find the modest amount of small diameter cable sagging between rungs to be unsightly.

For single conductor cables with an AWG of 1/0 through 4/0, the maximum distance between supports is 9 inches [1993 NEC Section 318-3(b)(1)].

The table below shows the latest retail May 2024 prices of Cable Tray in Philippines Peso price per pieces including its size and specification.

Price and Standard Sizes of Cable Tray per pc in the Philippines

| DESCRIPTION | SPECIFICATION | SIZE (W x D x H) | PRICE |

| Cable Tray | Hot Dipped Galvanized | 300 mm x 100 mm x 2.0 mm | 5300.00 |

| Cable Tray | Hot Dipped Galvanized | 300 mm x 150 mm x 2.0 mm | 5600.00 |

| Cable Tray | Hot Dipped Galvanized | 450 mm x 150 mm x 2.0 mm | 6400.00 |

| Cable Tray | Hot Dipped Galvanized | 600 mm x 100 mm x 2.0 mm | 7750.00 |

| Cable Tray | Hot Dipped Galvanized | 1000 mm x 100 mm x 2.0 mm | 12500.00 |

| Cable Tray | Hot Dipped Galvanized | 1200 mm x 100 mm x 2.0 mm | 13500.00 |

| Cable Tray | Vertical Elbow, HDG | 300 mm x 100 mm x 2.0 mm | 2650.00 |

| Cable Tray | Vertical Elbow, HDG | 450 mm x 150 mm x 2.0 mm | 3800.00 |

| Cable Tray | Vertical Elbow, HDG | 600 mm x 100 mm x 2.0 mm | 4200.00 |

| Cable Tray | Vertical Elbow, HDG | 1000 mm x 100 mm x 2.0 mm | 5900.00 |

| Cable Tray | Vertical Elbow, HDG | 1200 mm x 100 mm x 2.0 mm | 7500.00 |

| Cable Tray | Horizontal Elbow, HDG | 300 mm x 100 mm x 2.0 mm | 3400.00 |

| Cable Tray | Horizontal Elbow, HDG | 450 mm x 150 mm x 2.0 mm | 4900.00 |

| Cable Tray | Horizontal Elbow, HDG | 600 mm x 100 mm x 2.0 mm | 7000.00 |

| Cable Tray | Horizontal Elbow, HDG | 1000 mm x 100 mm x 2.0 mm | 14500.00 |

| Cable Tray | Horizontal Elbow, HDG | 1200 mm x 100 mm x 2.0 mm | 16500.00 |

| Cable Tray | Tee, HDG | 300 mm x 100 mm x 2.0 mm | 5500.00 |

| Cable Tray | Tee, HDG | 450 mm x 150 mm x 2.0 mm | 7500.00 |

| Cable Tray | Tee, HDG | 600 mm x 100 mm x 2.0 mm | 9500.00 |

| Cable Tray | Tee, HDG | 1000 mm x 100 mm x 2.0 mm | 17000.00 |

| Cable Tray | Tee, HDG | 1200 mm x 100 mm x 2.0 mm | 18500.00 |

UPDATED: Construction Material Prices for Cable Tray in the Philippines (May 2024)

UPDATED: All Construction Prices are based on retail prices around hardware in Metro Manila

To see other material construction, please see here.

To know other construction guides, tips, and methodology for beginners, veterans, and contractors, please see here.