Building projects have long used metal framing components. Metal studs have traditionally been utilized in commercial construction when fire protection and incombustibility are necessary to meet building and safety standards.

Residential construction projects are using metal stud framing systems more frequently because they are termite- and fire-resistant. For your construction needs in both commercial and residential building applications, a variety of metal stud materials are available.

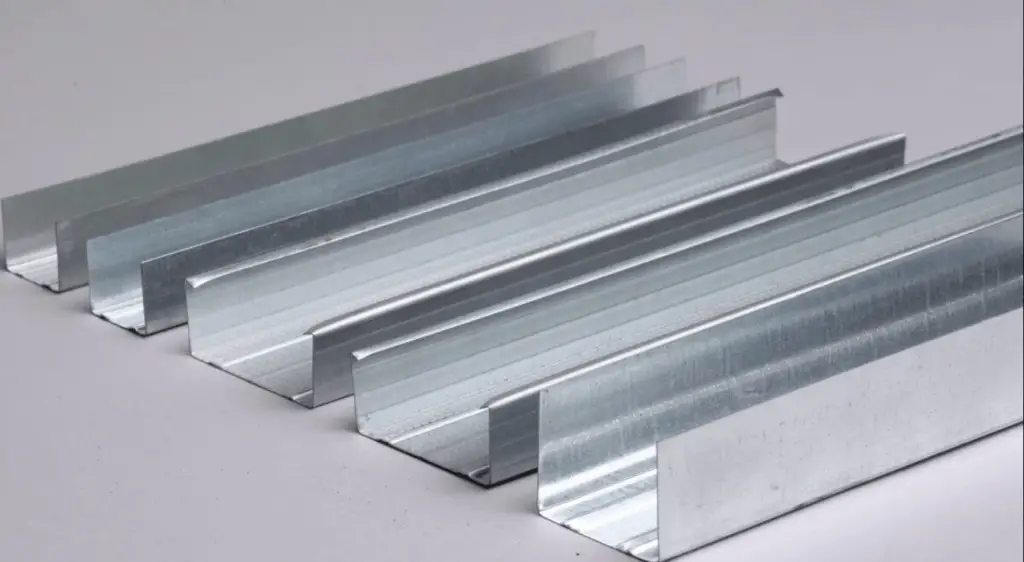

C-Shaped Metal Studs

Cold rolling machines are used to shape strips of galvanized steel into metal studs. The C-shaped stud contains three primary components when cut into cross sections. The part of the stud that determines stud dimension is called the web. 1-5/8, 2-1/2, 3-5/8, 4 and 6 inches are typical stud sizes. The web has horizontal strengthening holes where necessary and plumbing and electrical service access holes at regular intervals.

The area of the C-shaped stud where you will put wall-enclosing materials like drywall or acoustic boards is the flanges. A brief return completes the stud’s C shape, strengthening it. C-shaped studs can be ordered in custom lengths and portions of 8, 10, and 12 feet. Use these studs for situations that aren’t load bearing.

Metal Tracks Guaranteed Best Construction Material Philippines’ Prices

U-Shaped Channels

Each stud size has top and bottom tracks for placing the studs. When viewed in cross section, stud track has a simple U form and lacks a stiffening return. There are no regular punched openings on U channels. To align stud systems, attach these components to the floors and ceilings. To fix the U channel to floors and ceilings, use power-driven fasteners.

I-Shaped Metal Studs

There are metal studs available with a cross section that resembles an I. The metal stud’s web part is relocated to a location where it crosses the flanges’ center line. This particular stud is really stiff. Use I-shaped studs to create a frame around vertical shafts, ducts, and stairwells since wall surfacing materials can only be applied to the stud’s outer flange. Sizes for the I-stud are 2-1/2, 4, and 6 inches. Use this stud solely to construct non-load-bearing walls.

H-Shaped Metal Studs

A slightly heavier variation of metal studs with an I-shaped cross section is the H-shaped metal stud. The flange on H-shaped studs is broader and is used to receive wall finishes. There are custom lengths available in addition to the 8, 10, and 12 foot standard lengths. With this kind of stud, only non-load-bearing walls may be constructed.

S Metal Studs Construction Material Philippines’ Prices

Structural Metal Studs

Metal studs are made to serve as structural components of buildings. The metal used in structural metal studs is substantially thicker gauge. The configurations for stud widths include 2-1/2, 3-5/8, 6, and 8 inches. To suit particular building requirements, studs come in gauges of 20, 18, 16, 14 and 12. When creating load-bearing walls and partitions, use structural metal studs.

To see other material construction prices, please see here.

To know other construction guides, tips, and methodology for beginners, veterans, and contractors, please see here.

To know the flood prone areas in the Philippines, Top 10 Flood-Prone Areas to Live in the Philippines.