Expanded metal tolerances should be kept for:

- Sheet thickness

- Strand width

- Dimensions of openings

- Coating thickness

In general, expanded metal must not contain:

- Burrs

- Broken strands

- Laminations

- Welded strands

- Slivers

Tolerances in Expanded Metal

Expanded metal can be made with varying tolerances. These will be detailed below.

Camper Curve

This is the sheet’s bow or curve. If the enlarged metal sheets are going to be rolled up for packaging, it might not matter. In some situations, though, where more flat material is required, it might be unfavorable. This is particularly true if the material needed has a higher stiffness, which would cause the structure to experience residual stresses.

Producing expanded sheet metal without a camper is frequently quite uncommon. As a result, tolerances are set for specific applications. If the camper obtaining is outside the required tolerance, corrective action would be needed; else, the material is used satisfactorily.

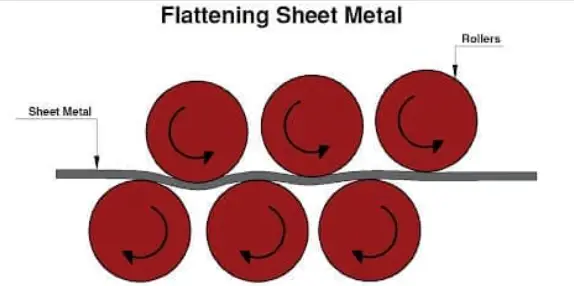

The edge that is parallel to the feed direction is typically where the curve forms (during the cutting and stretching stage of the expanding process). In most cases, rolling is also a part of the flattening process. Waves and buckles are frequently eliminated during the removal (or reduction) of campers, resulting in a more level final product.

Squareness Property

This is a characteristic of shapes that resemble rectangles or their special case, the square. Straight edges and 90° angles are crucial characteristics. The diagonals of such geometry are therefore equivalent.

Squareness is a planar property, which means that only one plane may satisfy it. When the sheet is on the ground and viewed from above, this is the plane that is visible. Without necessarily meeting all the other spatial and geometrical conditions, such as being level, an enlarged sheet might nevertheless be square. However, some spatial changes, such as folds and buckles, may prevent an expanded metal sheet from being square.

Even though the metal sheet is frequently made with extremely close tolerances, deviations from squareness are frequently caused by the sheet itself, which is rarely perfectly square. They may also result from flaws in the die that was used.

Re-squaring is accomplished by randomly shearing the enlarged metal sheet along the necessary lines, if the intended use permits. Stretching the shorter diagonal frequently results in non-straight edges while border shearing frequently has no re-squaring effect.

Parallel Sides

This quality is frequently necessary, particularly if the metal sheet being expanded has parallel (opposite) sides. Although parallel sides are a need for square sheets, parallel sides are not always a requirement for square sheets (the case in point being the parallelogram). Also, a sheet will never be square if its sides are not parallel. Campers are one of several things that might cause sides to not be parallel.

The expanded metal is purposefully made with non-parallel sides in specific purposes. Having a die with different-sized “teeth,” for instance, the teeth getting smaller over the width of the sheet, is one method of generating such expanded metal from a square solid sheet. However, these uses are quite rare.

Taper Sides

This is the divergence from parallel sides, which is especially obvious when a specific outcome is not desired. A sheet with tapering sides is not square, it should be noticed.

Expanded Metal Customization

The expanded metal sheet frequently needs additional treatment as soon as it exits the expanding machine. These tasks include cutting, bending, welding, bracing, and several others. Since each unique customisation is so large in scope, the aforementioned work is frequently not included in the production process. Additionally, some applications might call for expanded metal in a variety of gauges that work well together.

Therefore, customization refers to the processes that are carried out on the extended metal sheet, typically at the request of a particular customer. These jobs include:

- Slicing to match particular proportions

- Cutting to fit particular frame shapes

- Without removing any material or separating any portions of the original stretched sheet metal, shearing to create a tear or cut

- The sheets being bent

- Sheets being joined together

- Rolling to precise curvatures, such as changing the curvatures of several sheets at once

To know the pricelist of grout, Tile Grout Guaranteed Best Construction Material Philippines’ Prices

To know other construction guides, tips, and methodology for beginners, veterans, and contractors, please see here.

To know the flood prone areas in the Philippines, Top 10 Flood-Prone Areas to Live in the Philippines.

To know more about Concrete Hollow Blocks, Simple Reasons Why Hollow Blocks are Highly Used in the Philippines

To know more about Hammers and Nails, Tips for Guaranteed Best Technique for Hammering Nails

To know more about Tees and Wyes, What is the Guaranteed Best to Use: Sanitary Tee Vs Wye