Roll forming a sheet or strip of metal results in the creation of metal channels. A metal strip is continuously bent during roll forming as it travels through a series of rollers, often referred to as stands, which gradually deform a section of the metal until the desired shape is obtained. The produced sections are then trimmed to the required lengths after the shape and configuration process is finished.

Without the requirement for extra processing or finishing, roll forming is a cheap way to manufacture huge quantities of parts. Roll forming is able to create an infinite variety of metal channel profiles.

How Metal Channels are Roll Formed

CAD Design

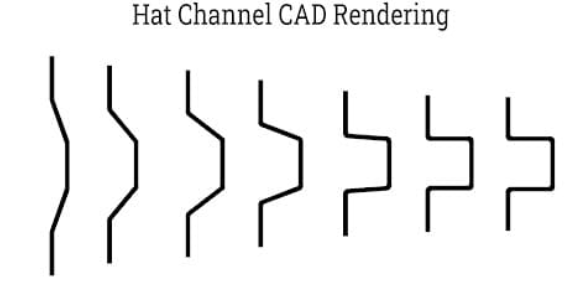

A computer-aided design (CAD) that incorporates the design aspects of geometry, length, and metal is the first step in the creation of all roll-formed parts, including metal channels. The design’s goal is to simplify production by presenting it as a single structure. Because of CAD’s flexibility, the part can be built by either entering its dimensions or sketching it directly into CAD. The application builds a nested and separated representation of the metal channel from the provided data. The evolution of the portion from stand to stand during the roll forming process may be seen in both images.

An illustration of the roll-forming of a hat channel in CAD is shown below. Directly from CAD, the information for the roll forming progressions can be extracted and converted into G codes for a computer numerical controlled (CNC) roll forming machine.

Sheet Metal Coil

A coil of metal positioned on an uncoiler, often referred to as a decoiler, serves as the basis for roll forming. The decoiler continuously feeds the roll of sheet metal into the roll forming machine. The uncoiler or decoiler may be made out to the right of the roll making machine in the photograph below.

Pre-Processing Treatment

In-line pre-processing is used to execute hole punching of slots, holes, notches, or specific custom patterns in metal channel roll formed parts. A programmable mechanical, pneumatic, or hydraulic machine applies force to the metal sheet using hardened tools with sharp cutting edges.

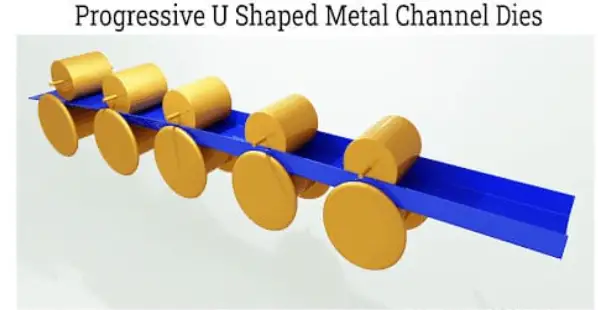

Roll Forming Dies

The roll forming machine contains a collection of precisely engineered dies installed in each of the stands in order to get ready for the roll forming process. These unique tools are created to perfectly suit the specifications of the metal channel that needs to be molded. The roll forming dies are separated into stations, each with a roller that gradually molds the metal sheet.

The progressive dies for forming a U-shaped metal channel are shown in the image below.

Roll Forming

The roll forming procedure starts after the CAD program has been downloaded and the dies have been positioned in the roll forming machine. The metal strip is pre-processed before entering an entry guide or table to ensure a square, straight entry into the first pass as it exits the uncoiler. To guarantee the caliber of the finished product, this step in the process is crucial. Depending on the complexity of the metal channel, the required number of passes might range from only a few to thirty or more.

Final Cut of Metal Channel

The start and finish of roll forming can be accomplished using a variety of techniques. In certain processes, straightening happens at the start, but in others, it happens at the conclusion. Whatever technique is being utilized, after the channel has been formed, the required length feeds out at the end, is cut to the precise measurements, and is then gathered on a table or pair of rollers.

The hydraulic cutting device seen below is seen cutting lengths of U-shaped metal channeling.

To know the pricelist of grout, Tile Grout Guaranteed Best Construction Material Philippines’ Prices

To know other construction guides, tips, and methodology for beginners, veterans, and contractors, please see here.

To know the flood prone areas in the Philippines, Top 10 Flood-Prone Areas to Live in the Philippines.

To know more about Concrete Hollow Blocks, Simple Reasons Why Hollow Blocks are Highly Used in the Philippines

To know more about Hammers and Nails, Tips for Guaranteed Best Technique for Hammering Nails

To know more about Tees and Wyes, What is the Guaranteed Best to Use: Sanitary Tee Vs Wye