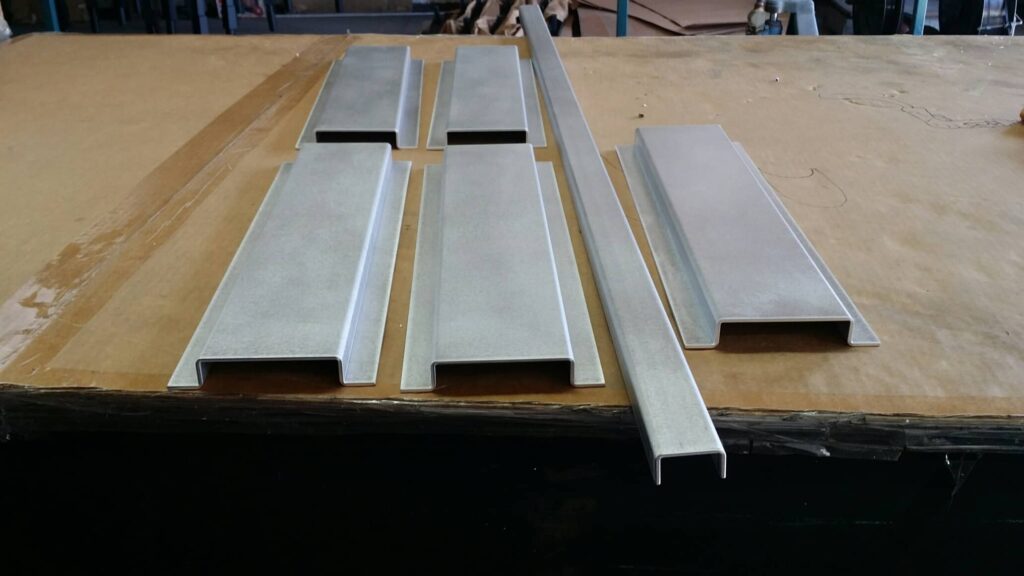

Although aluminum, different grades of stainless steel, and carbon steel are the most often utilized metals, there are relatively few restrictions on the sorts of metals that can be used to roll form metal channels. In order to produce a metal channel, a certain metal must be chosen, with heavier, more rigid metals being preferable for heavy load circumstances.

Shelves and secondary cross supports are supported by light metals like brass and aluminum. Steel is frequently utilized in construction projects for building rafters and studs.

Steel

Steel is the material of choice for the production of metal channels due to its strength and durability. Construction companies employ its structural strength to create braces and frames for buildings as well as supports for diverse machines and heavy machinery.

Aluminum

For the creation of metal channels, aluminum is the ideal material due to its strength and versatility. Despite not having the same tensile strength as steel, it provides sufficient stability to be employed as a support in some situations. Frame extensions, light poles, lighting fixtures, window and door frames, connectors, and the production of lightweight ladders all use aluminum channels. Metal channels made of aluminum are utilized as heat conductors and reflectors because of their good conductivity.

Brass

Metal channels are created using a variety of brass grades. Architectural bronze, also known as Brass 385, is a particularly strong and durable variety of brass that has outstanding corrosion resistance and is simple to shape and mold. Brass 385 is used as support for decorative applications such shelving and wall supports for exhibits and has a pleasing aesthetic look that polishes to a shiny finish. Exacting tolerances and lengths for any application can be created in brass.

Stainless Steel

Stainless steel is the perfect material for roll forming metal channels due to its different grades. Stainless steel comes in several grades, some of which have greater traits and attributes. The mechanical characteristics, resistance to corrosion, and appealing appearance of stainless steel are the key justifications for utilizing it. Stainless steel has become a standard in the production of goods for industries that need the highest levels of sanitation and cleanliness due to its resistance to corrosion and rust.

The grades of stainless steel that are frequently used include 304 and 316, with 304 being the more popular. Because stainless steel is alloyed with chromium and nickel, which gives it its resistance to oxidation and corrosion, it is incredibly strong. The second most popular grade of stainless steel is 316, which is marine grade.

Copper

Due to its ductility, which makes it incredibly simple to roll form into any of the several metal channel profiles, copper is primarily employed in roll forming. Copper is frequently alloyed with zinc to create brass and with tin to create bronze. The metals’ features and attributes are improved through alloying. The red metals are the collective name for all copper alloys. They maintain their initial strength even after going through the roll forming process.

Red metals resemble stainless steel in terms of resistance and form, but they lack the same degree of structural strength. Their durability is a remarkable and extraordinary quality. Once they have undergone oxidation, they are impervious to the impact and effects of the outside world.

To know the pricelist of grout, Tile Grout Guaranteed Best Construction Material Philippines’ Prices

To know other construction guides, tips, and methodology for beginners, veterans, and contractors, please see here.

To know the flood prone areas in the Philippines, Top 10 Flood-Prone Areas to Live in the Philippines.

To know more about Concrete Hollow Blocks, Simple Reasons Why Hollow Blocks are Highly Used in the Philippines

To know more about Hammers and Nails, Tips for Guaranteed Best Technique for Hammering Nails

To know more about Tees and Wyes, What is the Guaranteed Best to Use: Sanitary Tee Vs Wye