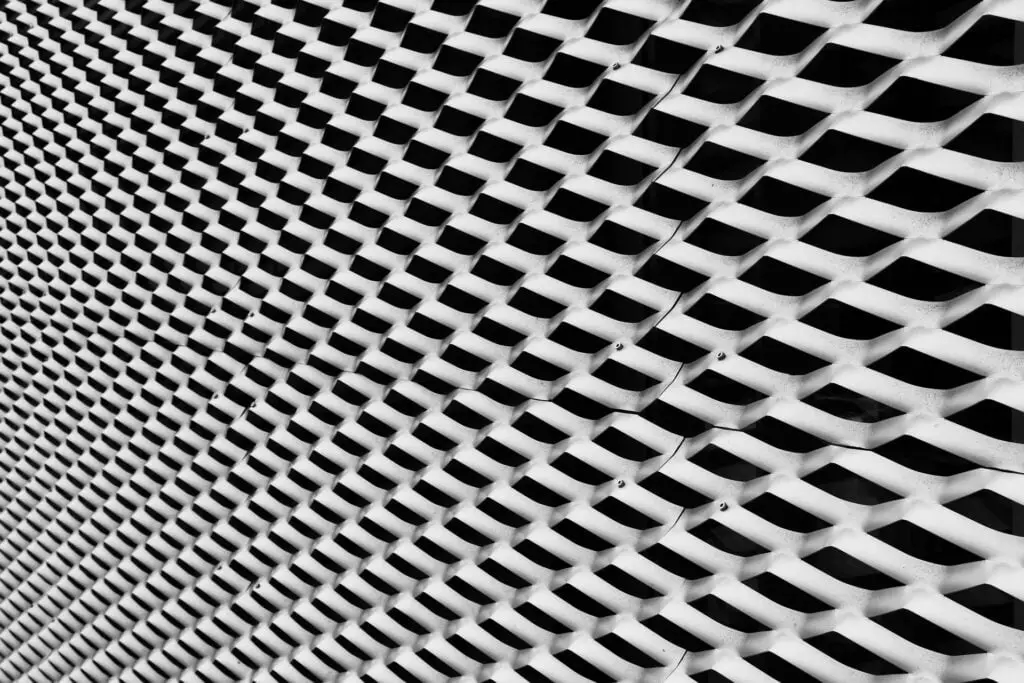

What Are The Guaranteed Different Expanded Metal

Sheet metal mesh is known as expanded metal. It is created by stretching a metal sheet that has been slit. The slits are oriented perpendicular to the stretch’s direction. Such stretching produces a variety of holes on the slits, giving the appearance of a mesh.

The premise behind it is that under different conditions, metals expand and contract, changing their size. The chemistry of these metals and the actions of their atoms lead to the most natural of these transformations. This results in the creation of expanded metal.

Expanded metal differs from and faces competition from the following:

Perforated Sheet

Punching holes, in this example into a metal sheet, is known as perforation. A sheet that has been perforated like this is made of metal. Sheets that may be perforated can frequently also be enlarged. Punching holes indicates the removal of material, which is what the subtractive process of perforation entails.

This has the drawback that the removed material is considered waste. The metal sheet that has been perforated is not always stretched as a result of the perforation.

The ability to create very small apertures and drainage casings for a variety of applications is one of its benefits. Additionally, it can contain shapes that are not possible with other meshing methods; this is useful if the mesh is meant to be aesthetic.

Woven Mesh

Metal wires are brought together more like the threads of fabric during this meshing process. Without friction and the wire’s stiffness, the weaving would not be held together, as there would be no bonding between the individual wires.

If the margins are not bonded, they often unravel. Sand sieving screens are frequently woven.

Welded Mesh

The two arrays of straight wires are stacked one on top of the other, perpendicular to one another. Anywhere any two wires connect, a welded joint is created. This mesh is typically utilized when there are significant gaps. Since more welds are needed to cover a given area, finer meshes are more difficult to manufacture.

Welded mesh is frequently used as reinforcement in concrete.

To know more about How to Apply Building Permit in the Philippines

To know other construction guides, tips, and methodology for beginners, veterans, and contractors, please see here.

To know the flood prone areas in the Philippines, Top 10 Flood-Prone Areas to Live in the Philippines.

To know more about Concrete Hollow Blocks, Simple Reasons Why Hollow Blocks are Highly Used in the Philippines

To know more about Surface Materials, What is the Best Surface Material: Laminate Vs. Veneer Vs. Solid Wood

To know more about House Construction, How to Build a House Cheaply: 7 Simple Ways to Save on Home Construction