Guaranteed Basic and Most Common Types of Wire Mesh

The numerous types of wire mesh are categorized according to their manufacturing processes, characteristics, uses, and weave patterns. Each of the numerous varieties is created to satisfy the demands of a project or application in terms of weight, strength, and finish. The finish, kind of metal, and type of pattern of the wire mesh are the deciding criteria, with the finish and metal being the main deciding factors.

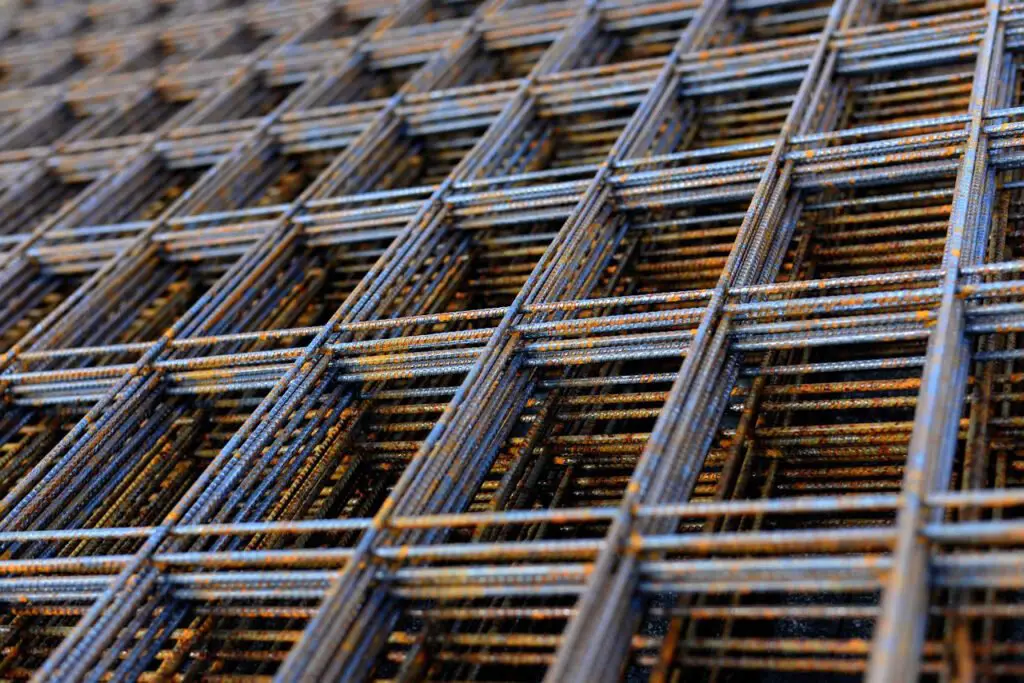

Welded Wire Mesh

The wire patterns in welded wire mesh are square. The sturdy mesh created by the welding technique is ideal for use as security fencing, room dividers, storage and racking in warehouses, storage lockers, and animal holding spaces in veterinary offices and animal shelters.

What is welded wire mesh?

- durable and able to tolerate weather changes

- firmly and securely held in position without creep or movement

- Adaptable to any dimensional requirements or specs

The durability and corrosion resistance of stainless steel are present in welded wire mesh.

Galvanized Wire Mesh

The raw or carbon steel wire used to create galvanized wire mesh is coated with zinc during the galvanizing process. The zinc layer serves as a shield to prevent corrosion and rust on the wire mesh. Galvanized wire or plain steel wire that has been woven or welded and then galvanized can be used to create galvanized wire mesh. Galvanizing the wire mesh after it has been prepared results in a higher-quality wire mesh but costs more than the other two processes.

Galvanized wire mesh is perfect for window guards, infill panels, greenhouse fencing, agricultural and gardening fencing, building and construction fencing, and security fencing. It is one of the more often utilized varieties of wire mesh because of its price.

Vinyl-Coated Wire Mesh

A sturdy barrier is made for very flexible wire mesh by applying a vinyl coating to welded or woven wire mesh. Vinyl-coated wire mesh is resistant to impacts, scrapes, and abrasions, and it maintains its stability across a wide temperature range.

Wire mesh is sometimes referred to as plastic mesh because of the vinyl covering that gives the appearance that the mesh is composed of plastic. Vinyl-coated wire mesh is resilient, long-lasting, and rust- and corrosion-resistant in addition to having a pleasing look. It protects the wires from contaminating factors like water.

Welded Steel Bar Gratings

Forge welding at extremely high temperatures is used to create welded steel bar gratings. In this method, parallel rows of rectangular bars are joined together by drawing perpendicular bars across them. The procedure produces a fused, durable bond that can resist the most difficult and dangerous circumstances. Steel that is used to make welded steel bar gratings is either carbon steel or stainless steel, and it is incredibly strong, stiff, and long-lasting.

Welded steel bar grating is used for industrial floors, ramps, ventilation grills, landing mats, and bridge decking because it can support heavy weights over a long period of time. Panels are produced in a variety of bar diameters, from 1″ to 6″ deep and 0.25″ up to 0.50″ thick, in widths of two to three feet and lengths of two feet.

Stainless Steel Wire Mesh

Stainless steel wire mesh offers superior performance and protection and has all the benefits of stainless steel. Wire mesh is frequently made of steel, however steel rusts quickly when exposed to air. With the addition of chromium, stainless steel, which is made of the same components as steel, is resistant to rust and shielded from oxidation.

Stainless steel is renowned for its dependability, sturdiness, and longevity in the production of wire mesh. Any outdoor application can use stainless steel because of its resistance to rust. It regularly provides durability and strength, making it the most widely used type of wire mesh.

Stainless steel can be welded or woven, as is the case with all types of wire mesh. The stainless steel grades used to make wire mesh include 304, 316, and 316L, with wire diameters ranging from 0.55 to 2.66 mm (0.22 to 0.105 inches), and apertures ranging from 1/4 inch to 1 inch (6.35–25.4 mm).

For maritime purposes, a superior alloy called grade 316 stainless steel is employed. It is available in fine, medium, or coarse diameters, has great corrosion resistance, and is unaffected by acids, salt water, or seawater. Although grade 304 stainless steel is very workable and less expensive than grade 316, it is not as corrosion resistant as grade 316.

To know the pricelist of grout, Tile Grout Guaranteed Best Construction Material Philippines’ Prices

To know other construction guides, tips, and methodology for beginners, veterans, and contractors, please see here.

To know the flood prone areas in the Philippines, Top 10 Flood-Prone Areas to Live in the Philippines.

To know more about Concrete Hollow Blocks, Simple Reasons Why Hollow Blocks are Highly Used in the Philippines

To know more about Hammers and Nails, Tips for Guaranteed Best Technique for Hammering Nails

To know more about Tees and Wyes, What is the Guaranteed Best to Use: Sanitary Tee Vs Wye